|

Traditionally each distillery had its own malting floor where the germinating seeds were regularly turned. Most of the distilleries use commercial "maltsters" who prepare each distillery’s malt to exact specifications, but the "pagoda roof" (many now false) which ventilated the malting floor can be seen at nearly every distillery.

The distinctive "pagoda" chimney of a kiln at a distillery in Scotland Malting

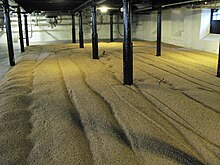

Malting floor at Highland Park Distillery. Barley, yeast and water are the only ingredients required in the production of single malt Scotch. The barley used to make the whisky is "malted" by soaking the grain in water for 2–3 days and then allowing it to germinate to produce the necessary enzymes required to convert starch into fermentable sugars. The germination is halted (by heating) after 3–5 days, before the starch begins to be converted into the fermentable sugars. The method for drying the germinated barley is by heating it with hot air produced by an oil, coal or even electric heat source. In most cases, some level of peat smoke is introduced to the kiln to add phenols, a smoky aroma and flavour to the whisky. Some of the more intensely smoky malts from Islay have phenol levels between 25 and 50 parts per million (ppm). The three smokiest/peatiest malts, in order of phenol concentration, are Ardbeg, Laphroaig, and Lagavulin, all from Islay. More subtle malts can have phenol levels of around 2–3 ppm. From Wikipedia, the free encyclopedia : Malting |